The conventional nuts are made up of a threaded hole that can get detached and loosen with vibrations. Lock nuts have a unique design that stops them from getting loose even when they experience torque or vibrations.

So, how do lock nuts work? What are the different types? Let’s explore the world of lock nuts further.

Classification of lock nuts

There are two examples of lock nuts –

1. Friction amid mating threads

This type of lock nut has dimpled grooves and requires substantial force to loosen or tighten them. They need a longer time to put together because they don’t freely revolve around on the shaft of the fastener and tighten as you twist them. They are known as “prevailing torque nuts” because they combat rotation while tightening or removing them.

The price tag is lower for this type of lock nuts versus other styles.

2. Positive locking device

These are nuts that have locks to them. They move easily while loosening or tightening, which makes for putting it together very fast. Although it is solid and has a quick assembly time, it costs more to buy than other lock nuts.

You must figure out what you value more – saving time or money. It will depend on the project and your feelings on the subject; however, you might want to spend more money for a faster time to put it all together.

Types of Lock Nuts

Sometimes the traditional nut isn’t the right fit for the job. The lock nut is often the answer when you need a nut that resists vibrational loosening. Different locking nuts are used for a plethora of reasons.

The most popular lock nuts are jam nuts, nylon inserts, and bearings.

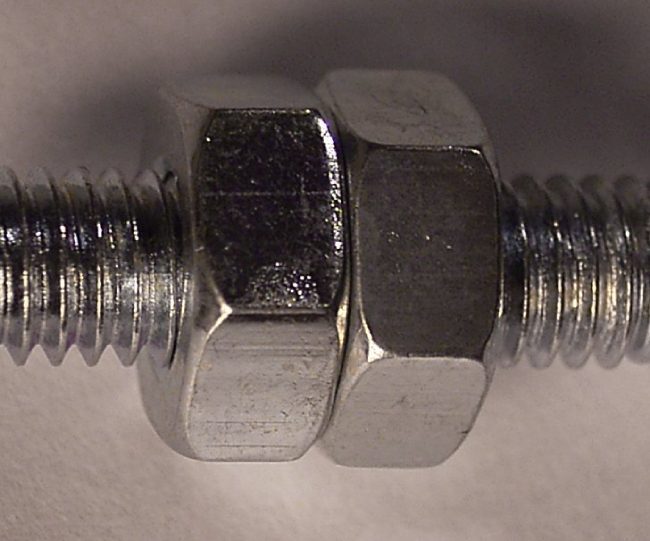

1. Jam nuts

**Photo Courtesy: Wikipedia

Also known as half nuts, they hinder vibration and movement from unbinding the bolted joint. Nowadays, some nuts have self-locking abilities; however, before that, you would have to use two of the jam nuts fastened together tightly so they wouldn’t come undone over time.

This type of nut isn’t recommended for vital work where putting it together requires tension or pressure load. Great for using them on specialty cars, pipelines, air, rail, and furniture.

2. Nylon inserts lock nuts

**Photo Courtesy: Amazon

These nuts also go by the name stop nuts or nylon nuts. Despite normal wear and tear, vibrations, and shock, they resist coming loose. These nuts are used for various projects but are restricted when in contact with temperatures 250 degrees Fahrenheit and under.

When installing the nylon insert lock nut, position the locking end, so it joins with the mating threads. It should thread easily until mating threads inside the host component engage the nylon insert.

They are used in streetlights, elevators, pipelines, lifting equipment, and furniture.

3. Bearing lock nuts

**Photo Courtesy: Chinhsing

These nuts are also called bearing retaining nuts or shaft locknuts. They are used to affix bearings onto a rod and to inhibit loosening because of rotation and movement.

Bearing nuts look different than other lock nuts because they have a curved exterior and keyed slots. They need a unique tool named a spanner socket or wrench to remove or install applications.

You will find the use of these nuts in many different things, including the agricultural and automotive industries.

Lock Nut Versus Lock Washer

Should you use a traditional lock washer or lock nut? This will depend on the types of nuts or washers it is and what they are being used for.

The capacity to manage the pressure of forcing down a screw or bolt is ideal for the lock washer.

For joint integrity that is sturdy and steadfast, it’s a good idea to use a nylon nut. If the area you are working in is tight, the nylon nut might be too cumbersome, and you will need to use a lock washer instead.

Both are viable options, but which one you use will depend on the factors involved.

How Do You Tighten Lock Nuts?

It’s considered to be a simple process. Just adhere to the following steps:

- Put the lock nut up against the bolt (threaded end).

- Tighten up the lock nut by hand. If the nut contains a raised area in the center, ensure the lock nut’s flat end sits tightly against the exterior when you tighten it.

- A torque wrench should be used to fasten the nut until the desired torque has been reached.

If you require lock nuts for heavy-duty or industrial applications, choose the following metal nuts:

- Brass

- Stainless steel

- Zinc-plated mild steel

Lock nuts that are metal boost the resistance to movement during assembly. They can also endure very high temperatures, whereas plastic lock nuts cannot. However, plastic is a viable option for things where the force of the torque isn’t over the top.

FAQs

1. Are nylon lock nuts reusable?

Ans. Many people debate this question. Sometimes you can reuse them, but every time you do, they weaken. Do not reuse a lock nut if you need the utmost safety for your application.

2. How does self-locking get assembled?

Ans. Every single lock nut has a smooth, rounded end. The top of the nut might be different, but the bottom of the nut is always smooth. The flat end is the thing that goes first over the bolt.

3. Can you remove the lock nuts?

Ans. Yes, they can. Rotate the lock nut clockwise. It will loosen from the screw or bolt that it was affixed to. Keep rotating it until you can pull it off with your hand.

Leave a Comment