Transmission fluid helps the transmission move gears easily, but it will also help prevent the car from overheating.

The fluid works as lubrication to extend the life of the transmission’s internal components.

Whether you have a problem with the transmission or the lines themselves, they will need to be removed before any work on the transmission gets started.

What is a Transmission Cooler Line and Does My Car Need One?

An engine that is running gives off extremely high temperatures.

Due to this, parts will become overheated. The transmission fluids work to keep the overall transmission system cool.

When you have hot fluid, it won’t be able to keep the transmission temps down.

The transmission cooler lines take the fluid over to the car’s radiator from the transmission. The fluid gets cooled down and then transferred back to keep it cool.

When Do You Need to Remove Transmission Cooler Lines?

The good thing about cooler lines is that they don’t break down from general wear and tear over time. Unfortunately, problems can occur, and faults do exist.

If you can see a red pool of liquid underneath your car, inspect the transmission or the cooling lines for leaks.

Once the car starts leaking fluid and gives off a burnt smell, it will head into complete malfunction. It may have already done damage to the transmission, so get it looked at asap to avoid further damage occurring.

If you are having problems shifting into gears, experiencing delays when you are shifting, or any of the above issues, you need to act right away for the safety of yourself and others when driving.

The lines will need to be repaired or replaced as soon as possible.

How to Tell If Your Cooling Lines Are Failing

1. Signs of Visible Damage

If you notice a sweet-smelling fluid that is bright green leaking from the car, this means you have a coolant leak.

You need to look at the cooler lines and see if you can find any damage, such as cracks or bulges.

2. Leaking Transmission Fluid

If you have a leak and can see transmission fluid on the area under the car, it might be a blown transmission line or a cooler failure.

Cooler lines can also rust, especially if you live near the ocean or in a humid climate.

A telltale sign is a red transmission fluid underneath the car. It can be an easy fix, but it will depend on where the leak is.

3. Automatic Transmission Shifting is Difficult

If the vehicle is not shifting easily from one gear to the other, you might have low transmission fluid. Many things can cause poor shifting response but a cooling line problem is the most common.

4. Low Fluid Levels

If there is a problem with your transmission lines, the fluid levels should be checked first.

You can do this with the dipstick. If the levels are low this indicates, you have a leak somewhere.

It doesn’t always mean the leak is in the lines, but this is the place to check first.

5. Cooling Lines with Visible Damage

Make sure you check your cooling lines often for any damage such as holes, cracks, or bulges. If the lines are not properly shaped then you have a problem.

6. Overheated Transmission

If your cooling system has a problem, then you might experience rising fluid temperatures.

The cooler works to keep fluid at a low temperature, especially when there is a clog within the cooling system.

A clog won’t allow the liquid to flow correctly, resulting in fluid overheating.

7. Burning Rubber Smell

A problem with the transmission cooling system can let off a burning smell. If you can smell something strange, you need to pull over and let the car cool down.

How to Remove Transmission Cooler Lines from Transmission?

Step 1: Prop up the car with a jack

You need to lift the front of your car up with a car jack. Use two jack stands to hold the weight of the car underneath the frame.

Step 2: Support the weight

You can lift the back of the car up with a floor jack under the differential, then under each axle at the differential position a jack to hold the weight.

Step 3: Drain out the transmission fluid

You can drain the fluid from the transmission right under the transmission pan. Most vehicles will have a drain plug for this that you remove with a wrench. If there is no drain plug, you will need to remove the pan.

- Loosen the bolts

- Insert a flathead screwdriver or similar in between the transmission and the pan

- Use the screwdriver to break the gasket away from the transmission

- Place a container underneath to catch the fluid

- Once it has stopped draining, remove the bolts to take out the pan

Step 4: Find the two cooler lines

Open the hood of the car and locate the two cooler lines. These lead to the bottom of your radiator.

Step 5: Remove those cooler lines

Method 1:

You are focusing on the inside curves with this method. You need to press them, so a line is left. The tool used is called the line detaching tool. They are round in shape and have a lifted portion. You can get some with handles to make the job easier.

- The line detaching tool needs to be fastened well around the tube right near the connecting screw.

- You need the lifted part to remain towards the screw

- Gently push the tool, so the lifted part moves inside the screw.

- If the tools feel stuck, then it has reached the limit

- Now you need to push it hard to create pressure

- The inside curves will bend and leave the line

Method 2

- This is where you take out the clip which is done from the outside. You will need a type of tool that has a thin, sharp, and strong end. A screwdriver works.

- You will find the outer curves that are from the wire clip will have a bit of a gap for the connecting screw

- Place the pointy side of your tool on the gap

- Press it with strength

- The will create a wider gap as the tool enters

- Put the wire in the outer position with your tool

- Now slowly increase the pressure but don’t allow the tool to come out

- This will help to loosen the wire clip

- You can then remove the clip, and the line will come out easily

Things to Focus on while Removing Transmission Cooler Lines

- The transmission fluid needs to be drained completely for whichever method you use

- Take care when you are removing the line as draining the fluid doesn’t always mean there is none left in the tube

- When you are pulling or pushing, ensure you have complete control. Increase the pressure slowly without being tempted to do it all of a sudden

- The tool used is very thin and can slip easily, so ensure you are careful not to hurt yourself or damage components under the hood

- Keep the wire clip in method two safe while you are performing the task. Don’t lose it

Types of Transmission Cooler Lines

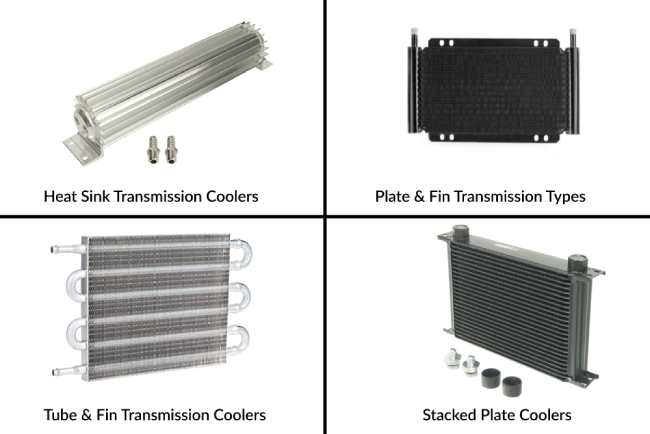

1. Heat Sink Transmission Coolers

The heat sink transmission coolers aren’t commonly used anymore. This type is mainly used on older vehicles.

Other trans coolers use incoming air to transfer heat, while these coolers use a unique finned aluminum design.

In heat sink transmission coolers, the fluid passageway within one or both passes is considerably larger than in other coolers, allowing the fluid to stay cooler for longer.

Pros

- Strong design

- There is no relying on airflow

- Still mountable in tight areas

- affordable

Cons

- not as effective as other types

2. Plate & Fin Transmission Types

The cooler works a little differently to maintain a degree of cooling efficacy. The fluid travels through parallel aluminum plates to increase the surface area to volume ratio instead of a tube-like type.

The horizontal plates increase the surface area to volume ratio of the fluid. Consequently, the fins will transfer heat more quickly.

As far as cooling transmission fluids is concerned, fin and plate coolers perform quite well.

They are also smaller in size than other coolers. This means that they are easy to fit into an automobile.

You will pay more for this cooling system than for a tube-fin cooler.

Pros

- Construction is durable

- Variety of sizes

- Cost-effective

- Better efficiency than the tube and fin

Cons

- Harder to install the larger ones

- Larger ones can be costly

3. Tube & Fin Transmission Coolers

Transmission coolers of this type are the simplest and least expensive. As the name implies, it has two main characteristics.

First, transmission fluid can flow into a tube that spreads heat and cools it using thin metal fins. To create a heat sink, the air is flown over the fins. A turbulator is also located inside the cooler.

By moving through the tubes, the turbulator agitates the transmission fluids. Heat is dispersed more effectively through the fins when the agitation is increased.

Aluminum fins collect heat, which transfers into the air surrounding the cooling units.

Pros

- Easy installation

- Least Expensive type

- Affordable

Cons

- Not as efficient as other types

4. Stacked Plate Coolers

The cooling efficiency of stackable plate coolers is higher. Stackable plate coolers are similar to plate and fin coolers. It is mainly the airflow involved that distinguishes the two coolers.

Air can easily circulate around the plates of the cooler. This results in a faster dispersion of heat. Coolers like these are perfect for racing and off-roading.

Some vehicles require higher cooling levels, so one with an integrated fans for increased airflow is best.

Pros

- Durable design and materials

- Larger cooling area

- Very efficient

Cons

- This type is the priciest

- Installation is complex due to the larger size

Differences Between Copper vs. Aluminum Transmission Cooler Lines

Both metals must be constructed the same for heat exchange to work effectively. As far as the thermal efficiency of aluminum exchangers is concerned, they will be just as efficient as their brass and copper counterparts.

The exchangers made out of aluminum are lighter and more efficient than those made out of steel.

In addition, aluminum coolers are extremely expensive to manufacture due to their complexity. Therefore, a protective black paint is applied to the metal as a barrier.

In place of accelerating, the heat transfer from the cooler to the surrounding air. It is best to paint and anodize the aluminum fins for them to work efficiently.

For the aluminum fillers, the baked heat exchange paint is preferred.

Cost of Repairing Transmission Cooler Lines

Having your transmission cooler lines repaired should cost you only $235 to $265.

You will pay about $125 for parts, and in most cases, it will cost you at least $100 for labor when repairing transmission cooler lines. Always ring around and get some quotes to get the best price.

FAQs

1. How long does cooling line replacement take?

Ans: The process of repairing your transmission’s cooling line can be time-consuming. It may take a day or two for your vehicle to undergo repairs.

In addition, your transmission is a complex engine component, so it will need to be fixed properly to ensure your vehicle is protected if a leak is found.

2. Can I use rubber hoses to replace the transmission cooling line?

Ans: Rubber hoses can be used for transmission cooler lines but it needs to be approved for that use. 12-15 psi pressure is required. Replace the worm-drive clamp with a double clamp or a FI-type clamp.

3. How long do transmission cooling lines last?

Ans: The transmission lines on your car should last for the vehicle’s lifetime. Unlike fuel filters, these don’t wear out over time and need to be changed regularly.

Unfortunately, there can be faults or problems that can cause you to replace or repair the transmission lines.

Leave a Comment